De-Risking Open Hole Casing Recovery

Ardyne has performed a challenging operation offshore Australia with the Downhole Power Tool (DHPT) and saved 3 days rig time for the operator. Why risk stuck casing and lost time when you could have 860 tons of pulling force standing by with a DHPT on the rig. Read our full case study here.

THE CHALLENGE:

A major operator mobilised a DHPT as contingency equipment for a multi-well P&A campaign on a semi submersible rig offshore Australia. The operation required the 9-5/8’’ casing to be recovered 102m outside the 13-3/8’’ shoe at an inclination of 54 degrees. The remaining casing piece was 113m long. An attempt to recover the casing with a conventional spear was conducted, pulling to a maximum of 920,000 lb force, but was not able to pull casing free.

Why did the conventional spear fail?

• The 54 degree inclination of the well caused a substantial amount of pulling force to be lost in friction.

• Settled solids and formation pressure held the casing downhole

• The rig did not have sufficient pulling force to free the casing at depth.

THE SOLUTION:

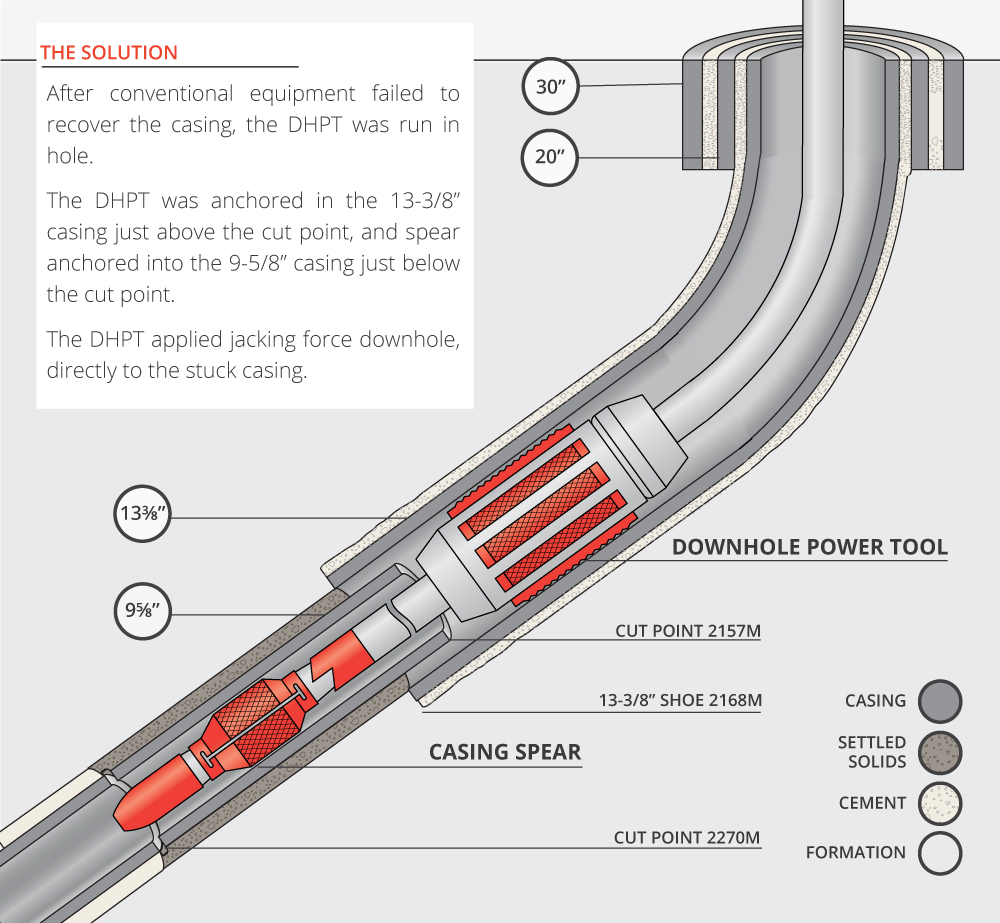

After conventional equipment failed to recover the casing, the DHPT was run in hole. The DHPT was anchored in the 13-3/8” casing just above the cut point, and spear anchored into the 9-5/8” casing just below the cut point. The DHPT applied jacking force downhole, directly to the stuck casing.

The DHPT generated upward pulling force of 550,000 lb to pull the casing free. The force was applied downhole directly to the stuck casing with no friction losses. After 16 strokes with the DHPT the casing was freed, and the rig was able to take over and recover the casing to surface.